The NP Aerospace–armoured Toyota Land Cruiser LC300 achieving VPAM VR7 BRV and ERV Edition 3 certification, including a 2‑meter side blast test with a third‑row seating layout, shows how detailed modern B7‑class specifications have become for civilian vehicles.

Key Takeaways

| Question | Answer |

|---|---|

| 1. What does BR7 / B7 mean on armored vehicles? | BR7 refers to protection tested against 7.62×51 armor‑piercing ammunition, a step above BR6, as unpacked in our guide on B4 to B7 ballistic protection levels. |

| 2. How is BR7 different from BR6 in practice? | BR6 commonly covers 7.62×39 and 7.62×51 ball rounds, while BR7 adds testing against armor‑piercing rounds, as we discuss in our BR6 versus BR7 implications overview. |

| 3. When do civilian buyers look at BR7 specs? | Organizations usually consider BR7 where higher ballistic resistance is required, a topic we frame inside broader selection advice in our armored car buyer’s guide. |

| 4. Are BR7 specs only for heavy APCs? | No, BR7‑class requirements appear in SUVs, pickups, and MRAP / APC platforms, which we group under our general armored vehicle category. |

| 5. How do geography and terrain affect BR7 choices? | Regions with long distances and rough roads often use BR6 and BR7 in SUVs and APCs, as outlined in our regional guides for Mozambique and Mali. |

| 6. Where can I see BR7‑relevant MRAP platforms? | We outline BR6 / BR7 capable MRAPs in our MRAP buyer’s guide and the dedicated APC SHARK overview. |

1. B7 Armor Basics: How BR7 Specs Are Defined And Tested

When people talk about “B7” or “BR7” armored vehicles, they are referring to a specific ballistic rating that focuses on protection against 7.62×51 armor‑piercing ammunition. In our own work, we treat BR7 specs as a complete package that affects chassis selection, weight distribution, and daily usability.

BR7 sits above BR6, which is usually tested against 7.62×39 and 7.62×51 ball ammunition, not armor‑piercing rounds. That seemingly small jump on paper drives significant changes in glass thickness, steel or composite layups, and how we engineer suspension and braking to carry the extra mass safely.

Key elements typically involved in BR7‑class spec discussions include:

- Ballistic resistance against 7.62×51 AP in specified test conditions (distance, angle, round count).

- Overlap and design of armor joints to reduce weak points at doors and pillars.

- Framing and mounting methods that keep armor structures stable under stress.

At SchutzCarr, we also pay close attention to how BR7 interfaces with other standards such as VPAM BRV/ERV or national norms, because those shape glazing, roof, and floor expectations in addition to side panels.

2. BR6 Versus BR7: What Changes In Real‑World Vehicle Specs

On paper, BR6 and BR7 are just adjacent lines in a table of ballistic ratings, yet in practice BR7 tends to require a deeper engineering rethink. We discuss this in detail in our internal BR6 versus BR7 analyses, where axle loads, braking capacity, and tire selection all shift as you move into B7‑class protection.

For vehicles originally designed as civilian SUVs or pickups, BR7 armor packages can add considerable weight versus BR6. That means we look at reinforced suspension components, upgraded wheels and tires, and often a different approach to payload management and seating layouts.

| Aspect | Typical BR6 Focus | Typical BR7 Focus |

|---|---|---|

| Ballistic threat | 7.62×39 / 7.62×51 ball | 7.62×51 armor‑piercing |

| Glass thickness | Lower relative thickness | Increased thickness and multi‑layer configurations |

| Chassis stress | Moderate weight increase | Higher weight, careful axle and frame evaluation |

Because of that extra mass, we do not treat BR7 as “just thicker steel” but as a full vehicle project that covers integration, long‑term service, and driver training. Clients looking at BR7 specs usually benefit from a line‑by‑line review of how each upgrade affects maintenance schedules and fleet planning.

3. VPAM VR7, BRV, ERV And Their Connection To B7 Specs

BR7 is often discussed alongside VPAM VR7 BRV and ERV, especially for modern SUVs. The NP Aerospace‑armoured LC300, for example, has been described as certified to VPAM VR7 BRV and ERV Edition 3, including a 2‑meter side blast test and third‑row seating.

In practice, VR7 / BRV / ERV specifications go beyond bullet resistance and look at blast effects, occupant survivability metrics, and how protection is distributed across the entire vehicle shell. For us, this means B7‑class projects are not just about armor materials but about how the whole vehicle behaves under extreme mechanical load.

- BRV focuses on ballistic resistance of the vehicle.

- ERV focuses on explosive resistance and blast conditions.

- VR7 is the combined vehicle rating that many clients associate with B7‑level performance.

By aligning B7 specs with VR7 / BRV / ERV standards, we can translate technical test language into practical implications for seating capacity, ingress/egress, and storage within SUVs and APCs.

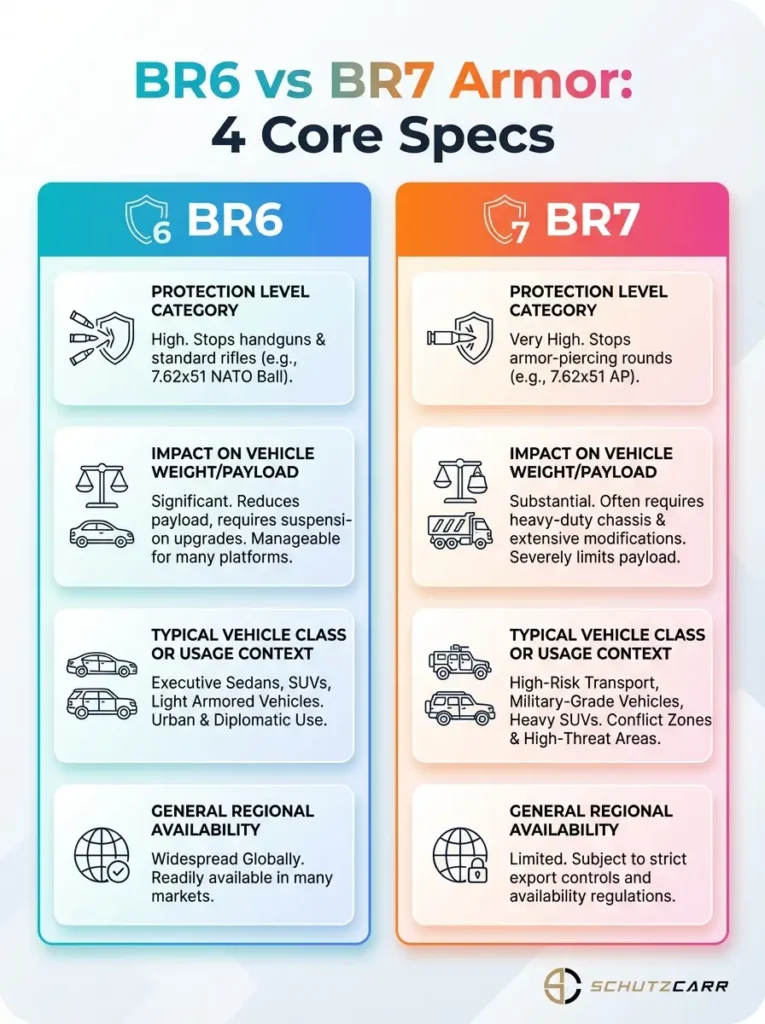

This infographic compares BR6 and BR7 armor for armored vehicles. It highlights four core specs to help evaluation.

4. B7 Specs On SUVs: From Land Cruiser Platforms To Executive Vehicles

While many people associate B7 with heavy APCs, the modern reality is that SUVs often carry BR6 and sometimes BR7‑class specs. Platforms like the Toyota Land Cruiser 76 and 300 GXR form the backbone of many civilian fleets, and we treat them as starting points when clients ask what B7‑oriented armoring would look like in practice.

Our guides on Land Cruiser platforms discuss how wheelbase, engine configuration, and chassis stiffness interact with heavy armor packages. For example, the longer LC300 wheelbase and independent suspension give different packaging options for armor, fuel tanks, and underbody protection compared to the ladder‑frame LC76.

When we design around BR6 or B7 specs for SUVs, we pay attention to:

- Door aperture geometry and how to maintain ergonomics with thick armor and glass.

- Weight balance front to rear after installing protected fuel tanks and run‑flat systems.

- Cooling system capacity, since heavier vehicles often work harder at low speeds.

Executive SUVs that pursue B7‑class specs also raise interior questions such as rear‑seat legroom, discreet styling, and climate control once heavy glass and multi‑layer insulation are in place.

Did You Know?

VPAM BRV/ERV Edition 3 and VR7 certification are now actively used on civilian vehicle platforms such as the LC300, with 2 m side‑blast qualification cited in multiple 2025–2026 technical reports.

5. B7‑Class Specs On MRAPs And APCs: APC SHARK And MONO Q Examples

MRAP‑style platforms and APCs are often where B7‑class requirements first appear in fleet planning. In our experience, these vehicles provide the chassis strength and suspension travel needed to carry heavier BR6 / BR7‑aligned armor layouts with more occupants and equipment.

APC SHARK Armored MRAP

Our APC SHARK is described as a civilian MRAP platform engineered around high levels of blast and ballistic protection, including BR6 / BR7 oriented solutions. From a specification perspective, that means a V‑style underbody, raised ride height, and reinforced axles and hubs sized for the combined weight of armor and passengers.

APC MONO Q 4×4 And Related Platforms

Vehicles like APC MONO Q 4×4 or GER 1D give us additional wheelbase and layout options for clients that want B7‑focused specs but different cabin or cargo arrangements. We also look at how tire size, steering geometry, and driveline components behave when operated consistently at armored gross vehicle weights.

For MRAP / APC projects, we typically review:

- Interior volume versus armor thickness and blast‑attenuating seating.

- Door, ramp, or step configurations that still work with added weight and height.

- Cooling and filtration systems sized for low‑speed, high‑heat environments.

6. Chassis, Axle Loads And Suspension: Why B7 Specs Start Under The Vehicle

B7‑class ballistic specs are written on test certificates, but they begin on the workshop floor with axle and suspension calculations. When we consider BR7 armor for any platform, we start by checking manufacturer axle ratings, frame construction, and the margin available for added mass.

For SUVs and pickups, this often leads to upgraded springs, shocks, and sometimes reinforced control arms or leaf packs. For MRAPs and APCs, we might specify heavier‑duty axles or different gear ratios so that the drivetrain operates within comfortable limits at armored weight.

We approach B7 specs as a system: armor, glass, suspension, brakes, steering, and tires all need to work together for predictable handling and braking distances.

This under‑the‑vehicle work is also where we address long‑term serviceability, making sure that components and consumables can be sourced and replaced without unusual delays.

7. Regional Use Cases: How B7 Specs Fit Different Environments

B7‑related discussions change when you move from city centers to long cross‑border routes or remote regions. In our guides for locations such as Mozambique, Chad, Niger, Mali, and Ivory Coast, we look at how road quality, climate, and maintenance infrastructure shape BR6 / BR7 choices.

For example, in Niger the focus often falls on armored SUVs, pickups, and APC‑style vehicles that can handle long distances and rough surfaces. Many users there concentrate on BR6 and sometimes BR7, depending on route profiles and organizational risk assessments.

- Mozambique: Diverse terrain with interest in modern armored platforms for safe mobility.

- Chad and Mali: Vast distances and mixed road surfaces increase the value of MRAP/APC chassis for B7‑oriented specs.

- Ivory Coast: Urban centers create demand for discreet armored SUVs and sedans, sometimes in BR6 / BR7 configurations.

By mapping B7‑class specifications to specific regions, we help clients match protection requirements with service and logistics realities.

Did You Know?

NP Aerospace projects production of over 100 LC300 armored vehicles in the next 12–18 months to meet growing demand for VR7/BR7‑class civilian protection platforms.

8. Interior Layout, Ergonomics And Visibility With B7‑Class Armor

B7‑level ballistic glass and door armor introduce practical questions inside the cabin. Thick multi‑layer glazing can change sightlines, add weight to doors, and modify how occupants enter or exit the vehicle.

We work to maintain comfortable seating positions and door opening angles, especially for rear occupants in SUVs and for full teams inside APCs. That often means re‑engineering hinges, latches, and step heights so that B7‑class armor does not make everyday use difficult.

Key interior considerations for BR7‑oriented specs include:

- Door assist mechanisms to handle heavy armored doors safely.

- Optimized window openings that balance visibility and ballistic performance.

- Air conditioning capacity increased to manage thermal load from thick glass and insulation.

On APC and MRAP platforms, we also look at lighting, communication equipment routing, and storage so that occupants can move easily even with additional structural elements in place.

9. Discreet B7‑Oriented Protection For Executive Transport

Not every client wants a vehicle that looks overtly armored from a distance. Discreet executive sedans and SUVs can still incorporate BR6 and, in some cases, B7‑aligned specifications while keeping an exterior profile close to factory appearance.

Our work with vehicles such as luxury SUVs and sedans for urban use focuses on subtle reinforcements, carefully matched paintwork, and wheel designs that blend with local expectations. Inside, the emphasis shifts to comfort, refined interiors, and low noise levels despite heavy glass and structural reinforcements.

- Door frames and pillars are re‑engineered internally so exterior lines stay clean.

- Suspension tuning aims to keep ride quality as close to original as possible.

- Interior trims are refitted around armor structures to maintain a factory‑grade look.

These discreet projects still begin with the same B7‑class design questions about weight, visibility, and ingress, but the visual end result is intentionally understated.

10. Planning A Fleet Around B7 Specs: Lifecycle, Training And Support

Choosing one B7‑class vehicle is a technical exercise, but planning a full fleet takes a broader view. We encourage clients to look at lifecycle implications, including parts supply, axle and brake service intervals, and driver familiarization for heavier vehicles.

B7‑level armor packages change how vehicles accelerate, brake, and corner. We therefore recommend incorporating basic familiarization training so drivers understand how the mass and center of gravity differ from unarmored versions.

From a fleet‑wide perspective, useful planning questions include:

- Which routes genuinely require B7‑aligned specs and which can operate with BR6.

- Where maintenance facilities exist that can service heavier suspensions and larger brakes.

- How to group vehicles so that spare parts and consumables can be standardized.

By covering these elements early, organizations can integrate B7‑class vehicles into daily operations more smoothly and support them properly over time.

Conclusion

B7 and BR7 specifications describe more than a ballistic rating; they define how a vehicle is engineered, how it behaves on the road, and how it can be supported across its life. Whether you are considering a single SUV or a mixed fleet of SUVs, pickups, and APCs, aligning B7‑class requirements with chassis capability, regional conditions, and interior needs is essential.

At SchutzCarr, we help clients navigate these decisions across platforms and regions, from early specification discussions to long‑term fleet planning. If you are evaluating armored vehicles with BR7 or B7‑level specs and want structured, practical guidance, we invite you to contact us directly through our SchutzCarr contact page.