Across multiple armor fleets, mission-capable rates declined for 16 of 18 tracked platforms over several years, which shows how easily reliability slips without disciplined maintenance. In this guide, we share practical armor maintenance best practices that we apply at SchutzCarr so owners can plan care that supports long-term performance and predictable uptime.

Key Takeaways

| Question | Answer & Relevant Resource |

|---|---|

| 1. What is the first rule of armor maintenance best practices? | Treat the vehicle as an integrated armored system, not a standard SUV. Our overview on maintenance scheduling for armored SUV fleets explains why separate checks for armor, suspension, and glass are essential. |

| 2. How do protection levels like BR6 and BR7 affect maintenance? | Higher protection levels increase weight and complexity, so they require closer attention to brakes, suspension, and tires. Our guide on armored car protection levels helps you understand how this impacts long-term care. |

| 3. Which platforms are easier to maintain over time? | Simple, widely supported chassis often offer predictable maintenance, as shown with platforms like the LC76 in our Toyota Land Cruiser 76 BR6 overview. |

| 4. How can I reduce unexpected downtime for my armored vehicles? | Use planned inspection intervals, consistent record keeping, and parts forecasting. We outline this approach in our guide on long-term armored vehicle ownership costs. |

| 5. Do luxury armored SUVs need different maintenance than utilitarian platforms? | Luxury platforms typically have more electronics and comfort systems that need regular checks. Our comparison of the best armored SUVs for civilian use shows how platform choice shapes the maintenance profile. |

| 6. How do discreet armored sedans fit into maintenance planning? | Their low-profile exterior hides significant reinforcement that must be inspected regularly. We discuss these specifics in our discreet armored sedans comparison guide. |

| 7. Where can I explore armored platforms that are built with maintainability in mind? | Our curated inventory in the armored vehicles category focuses on platforms we can support with clear maintenance guidance and documentation. |

1. Why Armor Maintenance Best Practices Matter More Than Most Owners Expect

Armored vehicles carry extra weight, specialized materials, and complex integration work, so neglecting maintenance can affect both drivability and protection performance. Since mission-capable rates have fallen for the majority of tracked armor platforms over recent years, we treat maintenance planning as a core part of ownership rather than an afterthought.

Our approach focuses on protecting the integrity of the armored capsule while keeping the host chassis healthy through disciplined inspection, fluids management, and system monitoring. We encourage clients to think in maintenance cycles, not isolated repairs, so every visit builds toward predictable reliability instead of short-term fixes.

2. Understanding Protection Levels And Their Maintenance Implications

Armor maintenance best practices start with understanding your protection level, because BR6 and BR7 configurations place different demands on suspension components, tires, and braking systems. Higher ballistic ratings use heavier glass and armor packages, so we schedule closer monitoring of wear items and structural mounting points.

We also encourage owners to match their inspection depth to their risk profile and usage pattern, rather than treating all armored vehicles the same. An SUV that spends most of its life on paved urban routes needs different preventive checks from a platform that regularly sees rough terrain or long-distance travel with full payload.

3. Scheduled Maintenance For Armored SUV Fleets: Consistency Over Heroics

For single vehicles and fleets, we rely on scheduled maintenance as the backbone of armor care instead of waiting for visible issues. Our fleet clients work with us to create interval-based inspections that cover drivetrain, armor integration points, glass delamination checks, and electrical loads specific to armored builds.

We design these schedules around mileage, hours of operation, and route conditions so they reflect real-world use. This structured approach allows owners to predict workshop time, plan driver rotation, and keep safety standards consistent across multiple vehicles instead of reacting to breakdowns one by one.

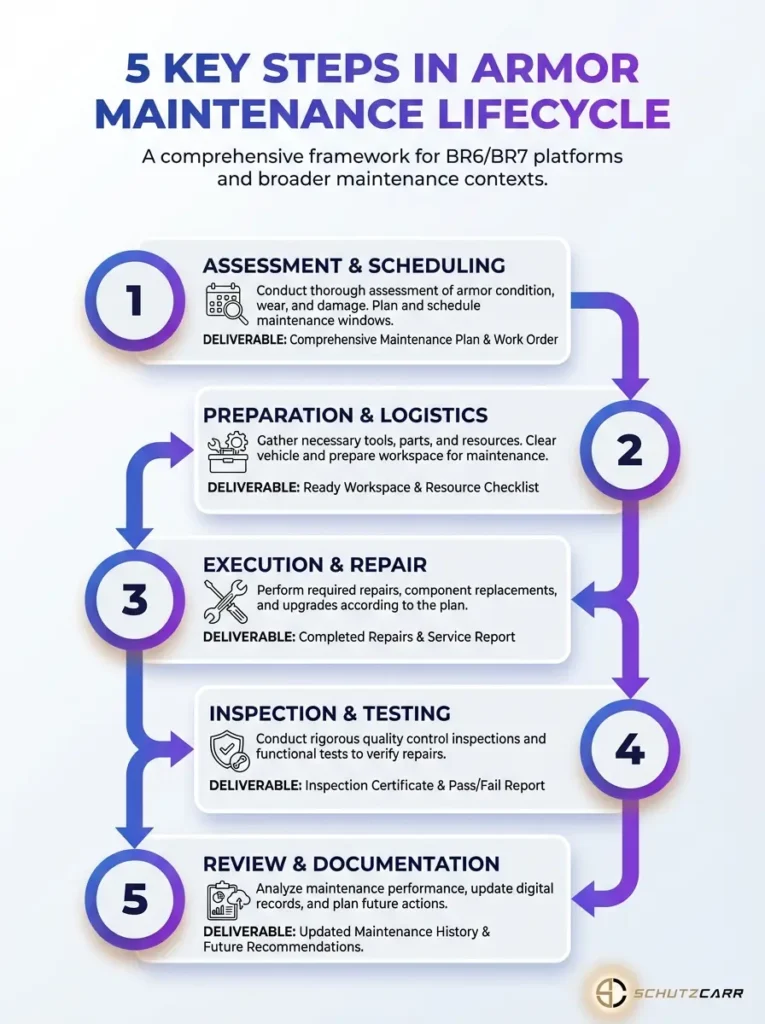

A concise visual guide to the five key steps in the armor maintenance lifecycle. Learn best practices to extend durability and reliability.

Did You Know?

Two sustainment challenges affecting all 18 vehicles in a GAO review were shortages of parts and not having current technical data or drawings.

4. Platform Choice And Long-Term Maintenance: LC76 And Similar Workhorses

Armor maintenance best practices begin at the platform selection stage, because some chassis are naturally easier to support over long service lives. The Toyota Land Cruiser 76 is a good example of a simple and durable platform that, when properly armored, supports straightforward service planning and predictable parts sourcing.

Our armored LC76 builds maintain drivability by reinforcing the chassis and correctly mounting ballistic glass and panels. This careful integration means that when you follow recommended maintenance intervals, routine checks for suspension, body mounts, and glass seals can be handled systematically instead of as one-off custom jobs.

5. Daily Use, Driver Habits, And Wear Patterns On Armored Vehicles

Even the best maintenance schedule cannot offset poor driving habits, which is why we coach owners on how acceleration, braking, and loading affect armored vehicles differently from standard SUVs. Extra mass means more energy in every stop and start, so aggressive driving accelerates brake wear, ball joint fatigue, and tire degradation.

We recommend simple driver protocols, such as gradual braking, careful ramp approach angles, and measured cornering, to reduce stress on armor mounts and chassis components. When drivers understand how their behavior affects service intervals, maintenance becomes a shared responsibility instead of something left only to workshops.

6. Luxury And Discreet Platforms: Extra Systems, Extra Checks

Luxury armored SUVs and discreet sedans introduce complex electronics, air suspension systems, and comfort features that require particular attention in a maintenance plan. From our experience with platforms like Maybach GLS 600 and executive sedans, the key is to layer standard chassis service with targeted checks for high-load electrical circuits, door mechanisms, and glass regulators that carry armored weight.

We also watch for subtle alignment shifts and body flex indicators, since luxury platforms often run at the high end of their original design envelope once armored. Owners of discreet sedans should factor in time for door seal inspections, underbody panel checks, and HVAC load tests, because these systems quietly work harder to support the additional mass and interior volume changes.

7. Total Cost Of Ownership: How Maintenance Practices Shape Long-Term Spend

Across many armor platforms, maintenance costs have risen significantly over multi-year periods, so owners benefit when they treat armor servicing as an investment in asset life rather than an occasional expense. We build cost models that consider scheduled services, likely wear part replacements, and inspection labor so owners can compare realistic lifecycle scenarios before they commit to a platform.

This planning approach reveals how preventive maintenance often reduces long-run spend compared with reactive repairs. By tracking wear trends and addressing early signs of fatigue, owners can avoid cascading failures that affect multiple components at once, such as a neglected suspension issue leading to tire edge wear and alignment problems.

Did You Know?

Maintenance costs increased for 9 of 11 tracked ground vehicles in a GAO review, highlighting how crucial efficient armor maintenance planning has become.

8. Documentation, Records, And Technical Data: The Backbone Of Good Maintenance

Reliable armor maintenance depends on accurate documentation, including build specifications, ballistic certification details, and up-to-date technical drawings. We supply complete build files for our platforms, along with guidance on service intervals tailored to the specific armoring package, so workshops have the information they need.

We also encourage owners to keep meticulous logbooks that record every service, inspection finding, and replacement part number. Over time, these records reveal trends such as recurring stress points, component lifespans under local conditions, and the real impact of route types on maintenance needs.

9. Comparing SUVs, Pickups, And APC-Style Platforms From A Maintenance Angle

Different armored body styles have distinct maintenance profiles, so we help owners compare SUVs, pickups, and APC-type platforms in terms of accessibility, part availability, and suspension demands. SUVs often provide a good balance of protection and serviceability for mixed-use profiles, while pickups can simplify certain drivetrain and load-path inspections.

APC-style vehicles carry heavier armor loads and specialized components, which can require more structured inspection routines and planned parts support. When you evaluate platforms like APC Merkava or TAV-based builds, it is important to factor in how easily workshops can access critical components and how often bushings, shocks, and steering parts will realistically need replacement.

10. Planning For Harsh Conditions: Desert, Urban, And Mixed Environments

Operating environments shape armor maintenance best practices, because dust, heat, humidity, and rough roads stress vehicles in different ways. In desert conditions, for example, we adjust inspection intervals for air filters, cooling systems, and suspension components that absorb constant vibration and abrasive dust.

Urban environments create their own wear patterns, such as frequent braking, curb impacts, and low-speed steering strain that affect tie rods, ball joints, and brake components. Mixed-use routes require flexible maintenance plans that incorporate both sets of checks, with special attention to armored glass seals, underbody protection, and door alignment that can shift gradually over time.

11. Integrating Armor Maintenance Into Vehicle Selection And Replacement Cycles

When owners choose new armored vehicles, we encourage them to consider maintenance requirements alongside protection level, comfort, and discretion. Platforms like the Land Cruiser 2024 Extended or Infiniti QX80 extended builds each have distinct service profiles, so we map out how maintenance scheduling, parts stocking, and workshop access will work in practice.

We also help clients plan replacement cycles that reflect realistic service lifespans and supportability horizons. By aligning acquisition decisions with a clear maintenance roadmap, owners can keep fleets modern, maintainable, and consistent in protection standards without facing sudden capability gaps caused by unplanned retirements.

Conclusion

Armor maintenance best practices come down to a few consistent principles: choose maintainable platforms, treat the vehicle as an integrated armored system, schedule inspections proactively, and keep accurate records. When owners and workshops follow these habits, armored vehicles remain predictable to operate, simpler to plan around, and easier to support throughout their lifecycle.

If you would like help building a maintenance plan for an existing armored vehicle or selecting a platform with long-term serviceability in mind, we invite you to contact our team. Reach out to us directly through the SchutzCarr contact page at https://schutzcarr.shop/contact/ so we can discuss your specific vehicle, routes, and maintenance goals in detail.