Unplanned downtime is rising across fleets, and 24% of operators now list it as a direct problem for their operation, which makes structured maintenance scheduling for armored SUV fleets more important than ever.

Key Takeaways

| Question | Short Answer |

|---|---|

| How often should armored SUVs receive preventive maintenance? | Intervals should be shorter than for non-armored vehicles because BR6 and higher protection increases weight and component stress. We recommend building a schedule aligned with your use case and the guidance in our armored SUV weight trade-offs overview. |

| What is different about maintaining armored SUVs vs regular SUVs? | Armored SUVs add ballistic glass, reinforced suspension, and chassis integration that require inspection patterns very different from standard vehicles, as outlined in our armored cars buyer’s guide. |

| Do protection levels like BR6 change maintenance schedules? | Yes, higher levels such as BR6 and BR7 increase vehicle mass, which affects braking, tires, and suspension wear. Our bulletproof car protection level guide helps map protection choices to maintenance impact. |

| Can luxury armored SUVs keep comfort while staying reliable? | Well engineered platforms like the armored Mercedes Maybach GLS 600 balance reinforcement and comfort, provided the fleet follows a disciplined maintenance schedule in line with the details in our GLS 600 armored SUV guide. |

| How do rugged platforms like the Land Cruiser 76 affect maintenance planning? | Rugged chassis can handle demanding terrain but still require careful monitoring of chassis and armor integration, as described in our Land Cruiser 76 armored platform overview. |

| Where can I see examples of armored SUVs that need structured maintenance schedules? | Our lineup includes BR6 armored SUVs such as the Infiniti QX80, which illustrates how luxury and heavy-duty components intersect for fleet maintenance planning in the Infiniti QX80 BR6 armored SUV guide. |

| Who can help design a maintenance schedule tailored to my armored fleet? | Our engineering team can help you design interval plans and inspection lists tailored to your operation. Use the form on our contact page to start the discussion. |

1. Why Maintenance Scheduling Matters So Much For Armored SUV Fleets

Armored SUVs carry greater mass, more complex structures, and specialized materials, so weak maintenance planning can quickly turn into repeated downtime and shortened vehicle lifecycles.

Predictive approaches show how powerful this can be: fleets using predictive maintenance have reported up to 75% reductions in unplanned downtime in some case studies, which highlights the value of a clear schedule backed by data.

Armored SUVs As A Distinct Fleet Category

Armored SUVs are not simply heavier versions of standard SUVs, because the armor integrates into the chassis, suspension, glass, and body shell as a single system.

That system needs periodic inspections that go well beyond oil changes and standard dealership services, especially once BR6 or higher protection is involved.

From Individual Vehicles To Managed Armored Fleets

When you manage a fleet instead of one or two vehicles, gaps in scheduling multiply quickly into missed assignments, logistical changes, and increased stress on the remaining vehicles.

A disciplined calendar for inspections, component replacement, and road tests lets you keep most of your fleet available while a smaller portion cycles through the workshop.

2. Core Principles Of Maintenance Scheduling For Armored SUV Fleets

We see the best results when fleet operators treat maintenance scheduling as a structured system built on a few clear principles instead of reacting to problems as they appear.

Those principles typically include a preventive maintenance calendar, condition monitoring of high-stress components, and standardized inspection checklists that align with your specific platforms.

Preventive Maintenance As Your Baseline

Industry data shows that fleets with strong preventive maintenance disciplines can move from a 55/45 split between scheduled and unscheduled work toward a 70/30 split, which means far fewer surprises.

For armored SUVs, that baseline often includes shorter service intervals and mandatory checks of suspension, tires, brakes, and door mechanisms after defined mileage or operating hours.

Condition-Based Adjustments For Heavy Components

Because BR6 armor adds weight, components such as dampers, control arms, ball joints, and brake systems experience higher loads and may not match standard replacement intervals listed in the original SUV owner’s manual.

We recommend that fleet managers track wear trends and adjust schedules component by component instead of copying standard SUV service plans.

3. How Armor Weight And Protection Levels Shape Your Service Intervals

BR6 and BR7 protection levels involve ballistic steel, composite armor, and thick ballistic glass that significantly increase the vehicle’s curb weight compared with a non-armored SUV.

This added mass transfers directly into higher loads on tires, brakes, driveline components, and the reinforced structure, which is why maintenance intervals for armored fleets cannot mirror standard SUV schedules.

Linking Protection Level To Maintenance Intensity

As protection levels move from B4 up to BR6 and B7, the mass increase and complexity of integration grow, which raises the importance of checking torque settings, welds, mounts, and seals more frequently.

Regular inspections of ballistic glass for delamination, seal gaps, and mechanical damage also need to be scheduled, because glass panels at BR6 specifications are heavier and more structurally involved than standard glazing.

Rugged Versus Executive Platforms And Their Scheduling Needs

Rugged platforms like the Toyota Land Cruiser 76 are typically set up for harsher terrain and may operate in dust, heat, and uneven road conditions that accelerate wear on suspension and filtration systems.

Executive platforms such as the Mercedes Maybach GLS 600 or Infiniti QX80 use complex air suspension and electronics, which call for scheduled diagnostics and software checks alongside mechanical work.

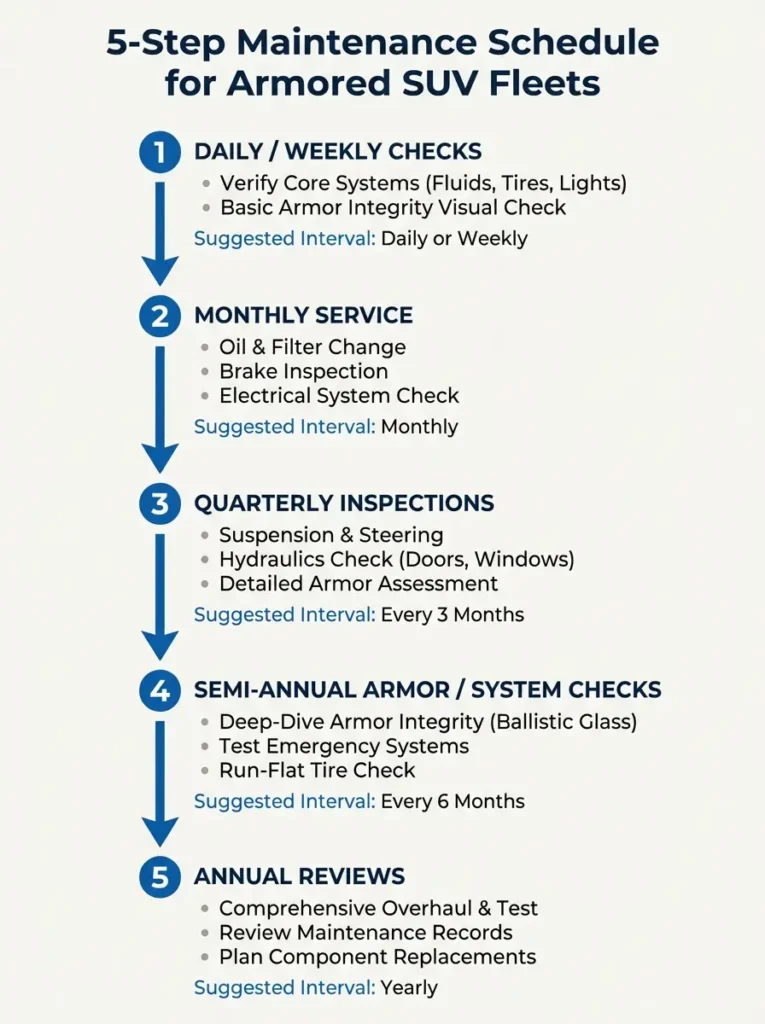

A concise 5-step visual guide showing the preventive maintenance schedule for armored SUV fleets to help fleet managers plan service intervals.

Did You Know?

Predictive maintenance reduces downtime: 60% of fleets reported fewer preventable breakdowns and 62% reported less unplanned downtime when relying on predictive maintenance.

4. Building A Preventive Maintenance Calendar For Armored SUVs

A practical preventive maintenance calendar for armored SUV fleets combines time-based and mileage-based triggers, then overlays them with your specific operating environment.

We usually recommend grouping services into light, medium, and major events, which lets you manage workshop capacity and plan which vehicles will be out of rotation on any given week.

Structuring Interval Bands

Light services might focus on fluids, filters, tire condition, and visual inspections of armor panels, doors, and glass, while medium services add suspension checks, torque audits, and brake system inspections.

Major services typically involve deeper diagnostics, possible component replacement based on tracked wear, and a full review of the armor integration points such as pillars, hinges, mounts, and underbody elements.

Sample Maintenance Calendar Layout

Many armored fleets find it useful to create a 12 month calendar that highlights which vehicles receive which level of service each month, adjusted for actual mileage and hours of operation.

Digital tools or simple spreadsheets can both work, as long as they provide a visible schedule, assigned responsibility, and a way to capture completed work for each armored SUV in the fleet.

| Interval Type | Main Focus Areas For Armored SUVs | Typical Triggers |

|---|---|---|

| Light service | Fluids, filters, tire wear, visual armor and glass checks, lighting, basic diagnostics | Short mileage band or monthly / bi‑monthly cycle |

| Medium service | Suspension, brakes, torque checks on armor mounts, underbody review | Larger mileage band or quarterly cycle |

| Major service | Detailed diagnostics, potential component replacement, full armor integration inspection | High mileage threshold or annual cycle |

5. Platform-Specific Scheduling: Land Cruiser 76, GLS 600, And QX80

Different armored SUV platforms bring distinct engineering foundations, which is why a single schedule template is rarely ideal for a mixed fleet.

At SchutzCarr we typically tailor maintenance schedules around the characteristics of each platform and the way that specific fleet operates them.

Armored Toyota Land Cruiser 76 Fleet Scheduling

The armored Toyota Land Cruiser 76, available in BR6 and BR7 configurations, uses a rugged chassis that is often chosen for demanding terrain and extended deployments away from major urban centers.

For these fleets, the schedule usually emphasizes drivetrain inspection, cooling system checks, and frequent underbody reviews to look for damage to armor plates, mounts, and protective elements.

Mercedes Maybach GLS 600 Armored SUV Scheduling

The armored Mercedes Maybach GLS 600 pairs BR6/FB6 protection with advanced suspension and a highly equipped interior, which introduces additional electronic and comfort systems to maintain.

We usually recommend schedules that incorporate regular diagnostics of the suspension controls, door and window mechanisms, and any integrated auxiliary systems, alongside the core mechanical checks.

Infiniti QX80 BR6 Armored SUV Scheduling

The Infiniti QX80 BR6 armored SUV, including extended wheelbase variants, combines a luxury interior with full perimeter protection and a reinforced structure.

Maintenance plans often focus on suspension geometry, tire loading, and brake performance, since these vehicles may carry multiple passengers and equipment regularly.

6. Predictive Maintenance And Data-Driven Scheduling

Traditional maintenance scheduling relies mainly on fixed intervals and technician feedback, while predictive maintenance uses data from the vehicles to anticipate failures earlier.

For armored SUV fleets, this can include monitoring parameters like brake temperatures, suspension travel, engine diagnostics, and even door cycle counts to refine when each vehicle should enter the workshop.

Why Predictive Approaches Fit Armored Fleets

Armored SUVs tend to operate in demanding environments with high stakes for reliability, which makes early detection of wear especially valuable.

Adopting predictive maintenance can cut maintenance costs by up to 30% and increase mean time between failures by about 50%, which directly supports higher availability for critical assignments.

Blending Preventive And Predictive Methods

We generally recommend using a preventive calendar as your backbone, then layering predictive insights on top to tweak timing and scope.

For example, if data suggests that certain components on a subset of GLS 600 vehicles are wearing faster, you can pull those vehicles forward for additional checks without changing the overall schedule for the rest of the fleet.

7. Uptime, Downtime, And Maintenance KPIs For Armored SUV Fleets

A schedule only works if you measure its effect, so defining a small set of KPIs for your armored SUV fleet is essential for continuous improvement.

Common fleet maintenance benchmarks include uptime percentage, scheduled versus unscheduled work ratio, and compliance with preventive maintenance events.

Useful KPI Targets

Industry benchmarks suggest that top performing fleets can reach uptime levels around 97 to 99%, while averages sit closer to 92 to 94%, and many fleets aim for above 95%.

Similarly, preventive maintenance compliance among top performers reaches 95 to 100%, while averages hover around 84%, so your goal should be to approach that higher band for armored fleets.

Tracking Metrics For Continuous Improvement

We recommend that armored SUV fleet managers review KPIs at regular intervals, identify the main sources of unplanned downtime, and feed those findings back into schedule design and parts planning.

Over time this loop allows you to reduce emergency repairs, adjust inspection focus, and allocate budget against the components that matter most for reliability.

Did You Know?

Scheduled vs. unscheduled maintenance for many fleets still sits around a 55/45 split, while best practice targets 70/30, highlighting how much room there is to shift work into planned maintenance windows.

8. Parts Planning, Supply, And Workshop Coordination

No maintenance schedule for armored SUV fleets can work reliably without stable access to parts and clear workshop coordination.

Recent fleet surveys show that 47% of operators plan to prioritize parts supply when making vehicle purchase decisions, which underlines how supply chains directly affect downtime.

Aligning Schedules With Parts Availability

We advise fleet managers to identify long-lead parts such as specific ballistic glass panels, armored door hardware, or reinforced suspension components and incorporate their lead times into the maintenance calendar.

By scheduling major services around confirmed parts availability, you minimize the risk of vehicles remaining off the road simply waiting for components.

Coordinating With Workshops And Technicians

Whether you use internal workshops or external partners, scheduling must reflect real capacity, technician skill sets, and any specialized tooling required for armored SUV work.

Sharing a quarterly or monthly maintenance plan with your workshop team allows them to prepare resources and reduces the likelihood of bottlenecks when multiple armored vehicles arrive at once.

9. Daily, Weekly, And Monthly Checks For Drivers And Fleet Teams

While scheduled workshop visits are crucial, day-to-day checks by drivers and fleet teams are the first line of defense for armored SUV reliability.

Short, repeatable checklists completed at the start or end of a shift help identify issues before they become failures on the road.

Daily Driver Walkaround Checks

Daily checks typically include tire inspection, visible leaks, lighting, mirrors, and a quick review of doors, windows, and any external armor panels for signs of damage or misalignment.

Interior checks can focus on warning lights, unusual noises, climate control operation, and any stiffness or unusual behavior in doors and windows.

Weekly And Monthly Fleet-Level Checks

Weekly checks may include more detailed tire pressure recording, fluid level logs, and short test drives to listen for suspension or brake noises under controlled conditions.

Monthly or bi-monthly reviews can align with light service intervals, adding underbody inspections and photo documentation of armor components to track any changes over time.

- Daily: Quick walkaround, basic interior functions, warning light check.

- Weekly: Tire pressures, fluid levels, short test drive observations.

- Monthly: Underbody review, armor mounting checks, documentation.

10. Documentation, Training, And Continuous Improvement

Reliable maintenance scheduling for armored SUV fleets depends on accurate documentation and consistent training, not only on the plan itself but also on how to execute it.

Over time, recorded data from services, inspections, and incidents becomes a valuable resource for refining intervals and identifying recurring issues.

Service Records And Configuration Control

We encourage fleet operators to keep detailed records for each armored SUV, including its configuration, any component upgrades, and a full history of inspections and repairs.

This documentation is particularly important for vehicles with BR6 or BR7 protection, where even small structural changes can have long-term implications if not recorded.

Training For Drivers And Technicians

Drivers benefit from training on daily checks, fault reporting, and understanding how armored components differ from standard vehicles, while technicians need guidance on safe procedures for working with ballistic glass, armor steel, and reinforcement structures.

As training and documentation improve, your maintenance schedules can move from generic templates to highly tuned plans that reflect the real behavior of your armored SUV fleet.

Conclusion

Maintenance scheduling for armored SUV fleets is most effective when it takes into account protection level, platform type, operating environment, and data from real-world use.

By combining a clear preventive maintenance calendar with predictive insights, strong parts planning, and consistent driver and technician routines, you can build a fleet that stays available and dependable under demanding conditions.

If you would like a maintenance schedule tailored to your specific armored SUV platforms and deployment patterns, our engineering team is ready to assist.

Use the form on our contact page to start a detailed conversation about your armored fleet and its maintenance strategy.