VPAM BRV 2009 certification sits at the center of how modern armored vehicles are designed, tested, and described, especially for BR6 level platforms. In this overview we explain what VPAM BRV 2009 is, how it connects to BR6 armoring, and how our SchutzCarr platforms align with these expectations in real-world use.

Key Takeaways

| Question | Answer |

|---|---|

| What is VPAM BRV 2009? | It is a vehicle ballistic test guideline used to evaluate how complete vehicles withstand specified ballistic threats, shaping how modern BR6 and similar protection packages are engineered and described in our discreet armored sedans guide. |

| How does VPAM BRV 2009 relate to BR6? | BR6 is a commonly referenced civilian protection level that aligns with rifle-resistant performance expectations, and VPAM BRV 2009 offers a structured way to test vehicles that are built around this kind of protection level, such as our Toyota Land Cruiser 76 BR6 platform. |

| Why does VPAM BRV 2009 matter for SUVs? | SUVs like the Toyota Land Cruiser 300 and Range Rover P530 often use BR6 type armoring, and VPAM BRV 2009 style testing helps evaluate how these complete vehicles perform when armored, as discussed in our Land Cruiser 300 GXR BR6 configurations guide. |

| Is VPAM BRV 2009 only for sedans? | No, the principles apply to a wide range of vehicle types, including luxury SUVs and extended BR6 builds like our Land Cruiser 300 BR6 Extended. |

| How does VPAM BRV 2009 interact with other standards? | Vehicle-focused VPAM BRV testing is often considered together with glass and material standards such as CEN 1063 and 1522, which you see reflected in platforms like our Range Rover P530 BR6 Extended. |

| Can VPAM BRV 2009 concepts apply to luxury-focused builds? | Yes, discreet luxury builds such as the Lexus LX600 BR6 armored platform integrate ballistic expectations in a way that preserves comfort and daily usability. |

| Are there VPAM-style solutions for rapid deployment? | Our dedicated regional pages, such as SchutzCarr Armored Vehicles Rwanda, focus on rapid availability of certified stock that follows structured ballistic standards and methodologies. |

1. VPAM BRV 2009 Certification Overview: Core Purpose And Scope

VPAM BRV 2009 is a guideline used to test complete vehicles against specified ballistic threats in a repeatable and documented way. It focuses on how the entire vehicle system reacts, not just individual materials in isolation.

In our work, we treat VPAM BRV 2009 as a framework that informs how we design, specify, and describe armored platforms for clients. It provides shared language for discussions about protection expectations and testing approaches.

How VPAM BRV 2009 Fits Into The Certification Landscape

Material and glass standards such as CEN 1063 (for transparent armor) and CEN 1522 (for opaque elements and window frames) focus on the components themselves. VPAM BRV 2009 then looks at the way these components are integrated into a complete vehicle.

This system-level view is crucial for understanding real-world performance, especially on BR6 platforms that require careful integration of armor, glass, structure, and vehicle dynamics.

2. From BRV 1999 To BRV 2009: Why The Update Matters

VPAM BRV 1999 was an earlier iteration of vehicle ballistic testing, and many industry discussions still refer to it. VPAM BRV 2009 refined those ideas, clarified procedures, and better aligned with the way modern armored vehicles are constructed.

When we talk to clients about BR6 and other levels, we often reference how the 2009 guideline influences test angles, shot placement logic, and assessment criteria for cabin integrity.

Key Improvements Introduced In BRV 2009

- Clearer description of test setups and measurement points on the vehicle body.

- More detailed treatment of hit patterns and shot grouping around structurally sensitive areas.

- Better alignment between opaque and transparent armor evaluation in the vehicle context.

These refinements give engineers, certifiers, and buyers a more consistent picture of how a BR6 type vehicle has been evaluated.

3. How VPAM BRV 2009 Relates To BR6 And Other Civilian Protection Levels

BR6 is a popular protection reference in the civilian market, often associated with resistance to common rifle calibers at specified distances and angles. VPAM BRV 2009 provides a process to test how a vehicle configured to that level behaves under controlled ballistic evaluation.

On a practical level, this means a BR6 labeled platform should have its opaque and transparent armor, as well as structural joints, designed to work together according to expectations framed by guidelines like BRV 2009.

BR6, CEN Standards, And BRV 2009 In One Picture

- CEN 1063 / 1522: Focus on glass and armor panel ratings (for example BR6 / FB6).

- VPAM BRV 2009: Focus on full vehicle testing at those or similar ballistic levels.

- Platform engineering: Focus on how weight, suspension, brakes, and structure cope with the armored capsule.

Clients see this come together most clearly when we walk through a specific platform and show how the BR6 label is supported by standards and testing methodology rather than marketing wording.

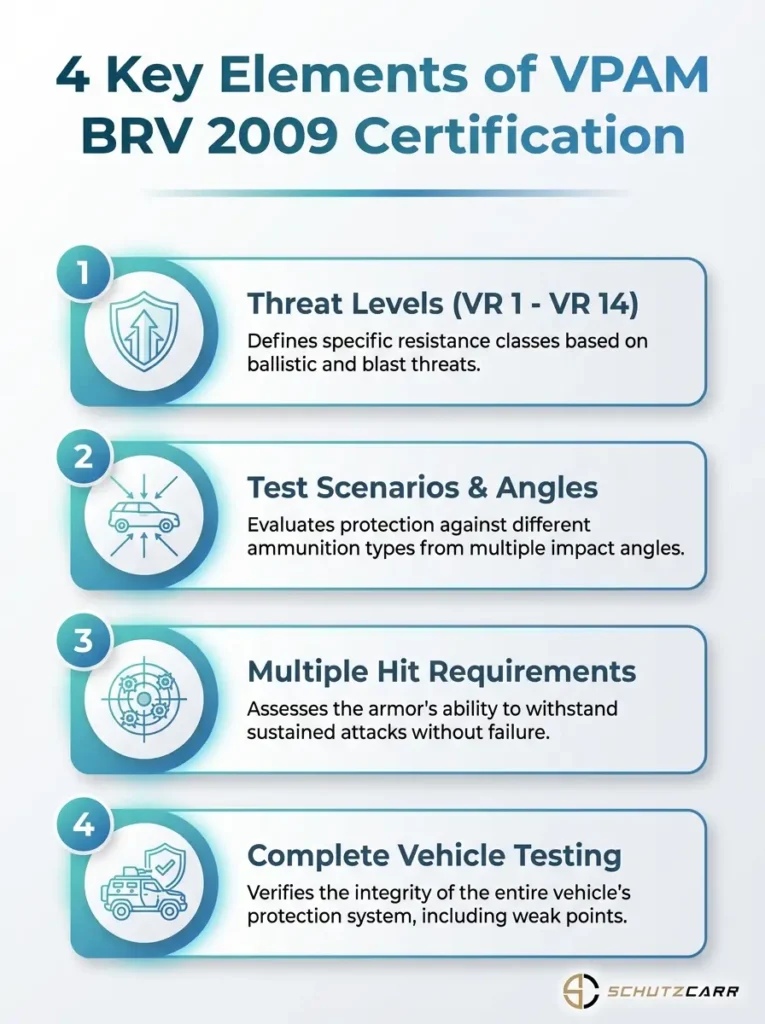

This infographic highlights the four essential elements of VPAM BRV 2009 Certification. It provides a quick visual reference for understanding the standard.

4. VPAM BRV 2009 Test Logic: What Gets Evaluated On The Vehicle

Although specific test protocols are handled by accredited facilities, it is useful for buyers to know which parts of the vehicle typically receive focused attention. VPAM BRV 2009 style testing considers critical zones where real-world threats are most likely to target structural weaknesses.

This usually includes shot groupings around door overlaps, window borders, roof pillars, firewall sections, and cargo or tailgate interfaces, along with representative points on the roof and floor.

Cabin Integrity And Residual Risk

The central objective is to protect cabin integrity. That means preventing penetration through the passenger cell and controlling spall or fragmentation behavior according to preset criteria.

During design, we treat these areas as system interfaces rather than individual plates, which ensures that BR6 labeling reflects a coordinated protection concept rather than a set of isolated panels.

5. VPAM BRV 2009 And The Toyota Land Cruiser 76 BR6 Platform

The Toyota Land Cruiser 76 is a well known base platform for BR6 armoring because of its robust chassis and simple mechanical layout. Our BR6 configuration focuses on building a full armored capsule that aligns with expectations shaped by VPAM BRV 2009 style testing.

Opaque armor, ballistic glass, and structural reinforcement are arranged to provide continuous coverage around the cabin, paying particular attention to roof, floor, and pillar intersections where real-world stress concentrates.

Land Cruiser 76 BR6: Protection Focus Areas

- Full cabin encapsulation with BR6 type armor around doors, pillars, and roof sections.

- Ballistic glass matched to the opaque armor to avoid mismatched threat ratings.

- Reinforced hinges, latches, and overlaps to address typical test shot placements.

By using the logic of VPAM BRV 2009 for design guidance, we can maintain a clear internal checklist of critical joints and coverage zones that matter most for occupants.

6. VPAM BRV 2009 In The Context Of The Land Cruiser 300 GXR BR6 Builds

The Toyota Land Cruiser 300 GXR sits at the center of current armored SUV demand, especially for discreet executive use. In our guide to this platform, we describe how BR6 configurations are laid out around the cabin with 360 degree coverage and integrated run-flat systems.

VPAM BRV 2009 logic influences how we think about door geometry, glass size, and overlap design on the LC300, which has more complex body shapes than earlier generations.

Designing BR6 Layouts For LC300 Under BRV-Inspired Principles

- Optimizing glass cut sizes to balance visibility with manageable ballistic panel dimensions.

- Managing weight distribution around the chassis to preserve handling with full BR6 capsules.

- Ensuring that tailgate and cargo areas integrate securely with the passenger cell armor.

The result is a BR6 type build that is not only defined on paper but follows the structural thinking that VPAM BRV 2009 testing would examine in practice.

7. Extended BR6 Builds And VPAM BRV 2009: Land Cruiser 300 BR6 Extended

Extended BR6 builds, such as our Land Cruiser 300 BR6 Extended, provide an opportunity to see VPAM BRV 2009 concepts applied over a larger physical envelope. Here, the entire vehicle is configured as an armored capsule with 360 degree coverage using BR6 / FB6 certified components under CEN 1063 / 1522.

The design includes extended armor in the doors and floors, which addresses typical weak points that a structured test would examine around sills, steps, and lower body intersections.

Why Floor And Door Extensions Matter Under BRV Logic

- Floor armor helps protect against low angle ballistic paths targeting underbody zones.

- Extended door armor minimizes exposure from off-axis or angled shots that could bypass central panel areas.

- Reinforced B and C pillars maintain overall capsule rigidity under impact.

When clients review this platform, we often map these areas visually so they can connect the extended BR6 description with how a VPAM style test would interact with those joints.

8. Discreet VPAM-Style Protection For Executives: Sedans And SUV Platforms

Our discreet armored sedans guide explains how executive protection has shifted from traditional sedans to SUV-based platforms that retain a low profile in public. VPAM BRV 2009 underpins the way we think about these builds, even when the exterior appearance is intentionally subtle.

Key examples include the Range Rover P530 Extended, Lexus LX600, and Toyota Land Cruiser 300 GXR, which all use BR6 or comparable protection layouts tailored for daily city and intercity use.

Balancing Discretion, Comfort, And Ballistic Structure

- Preserving factory-like interiors while embedding armor around pillars and rooflines.

- Aligning window shapes with ballistic glass thicknesses appropriate to BR6 type expectations.

- Maintaining ride quality through suspension and brake upgrades that offset armor weight.

This approach allows executive teams to travel in vehicles that do not advertise their protection level, yet are designed with the same structured thinking that BRV methodologies encourage.

9. VPAM BRV 2009, Stock Availability, And Deployment Planning

From a planning perspective, understanding VPAM BRV 2009 helps organizations evaluate not only the protection level of a vehicle but also how quickly that level can be made available. Our armored vehicle stock focuses on platforms that already follow these structural principles so that deployment timelines are practical.

This is particularly relevant where vehicles need to be introduced into service with minimal delay, and clients want clarity on what kind of ballistic methodology informed the build.

Using Certification Language To Clarify Fleet Decisions

- Aligning internal risk profiles with specific protection levels like BR6.

- Documenting how stock vehicles have been built in relation to VPAM BRV style principles.

- Planning driver training and maintenance schedules around armored-specific characteristics.

Even when a client is not directly involved in laboratory testing, the language of VPAM BRV 2009 provides a consistent reference point for technical discussions and procurement documentation.

10. How Buyers Can Use VPAM BRV 2009 When Comparing Armored Vehicles

For buyers, VPAM BRV 2009 is most useful as a structured checklist and a shared vocabulary, rather than a standalone marketing term. When reviewing proposals or technical sheets, we encourage clients to ask how the armoring concept aligns with VPAM style testing.

This includes confirming that opaque and transparent armor are matched, understanding which parts of the vehicle form the hardened capsule, and clarifying whether the design considers typical shot placements identified in BRV methodologies.

Practical Comparison Checklist

- Clarify the stated protection level (for example BR6) and related material standards such as CEN 1063 / 1522.

- Ask how the armoring layout addresses roof, floor, pillars, and joint zones.

- Confirm that glass, doors, overlaps, and tailgate interfaces are treated as part of one capsule.

- Review how weight, suspension, and braking have been adjusted for the armored configuration.

Using these questions, buyers can move from general labels to a more precise understanding of how closely a platform’s concept aligns with VPAM BRV 2009 style expectations.

Conclusion

VPAM BRV 2009 sits at the heart of modern armored vehicle engineering because it links ballistic theory to real vehicles in a structured, testable way. For BR6 platforms in particular, it provides a valuable framework for thinking about full-cabin protection, joint design, and how opaque and transparent armor work together.

At SchutzCarr we use the concepts behind VPAM BRV 2009 to guide our platform design, internal quality checks, and the way we explain protection levels to clients. If you would like to discuss how these principles apply to a specific project or platform, we invite you to contact us directly at https://schutzcarr.shop/contact/.